Some Text.

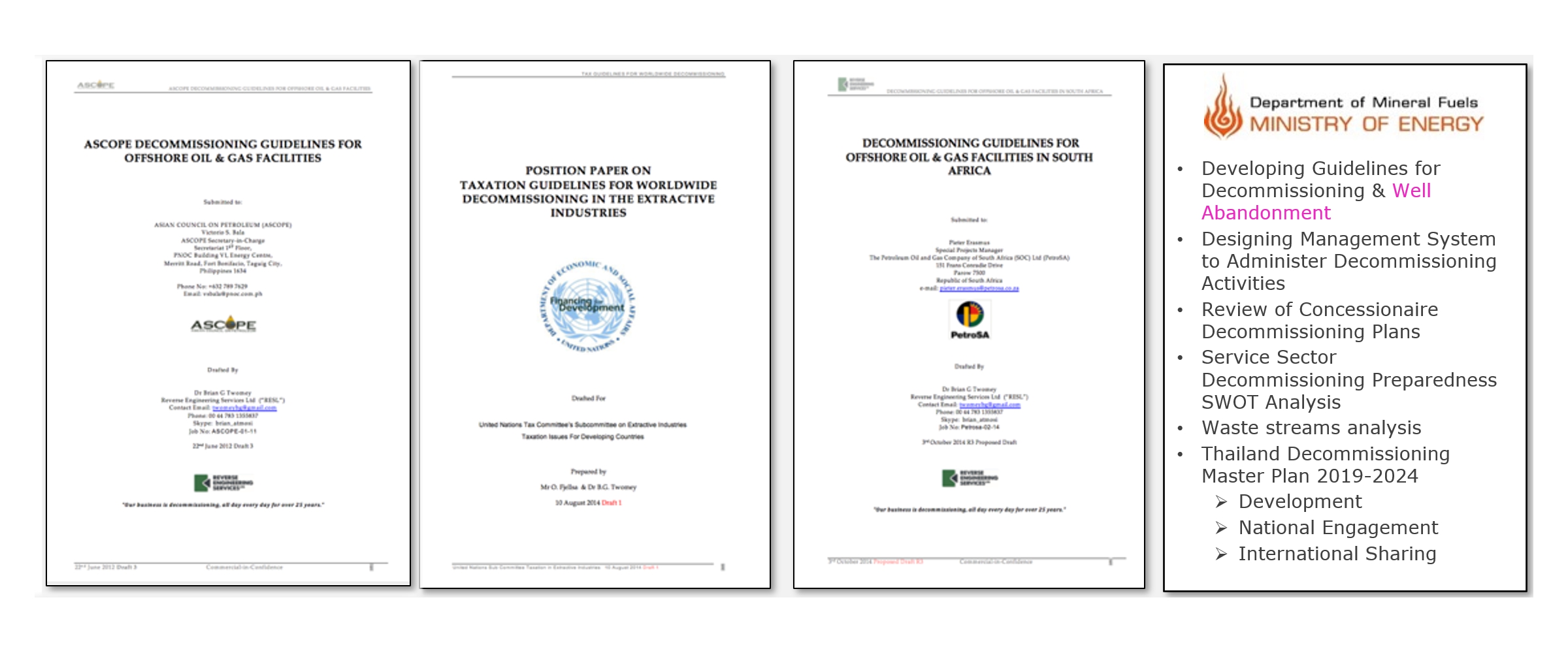

Over 30 years dedicated to decommissioning, ship recycling and well P&A.

To date, Reverse Engineering Services (RESL) has completed decommissioning work on over 870 sites, more than 1,876 well P&A’s, numerous pipelines, and subsea systems, including 22 floating production storage and offloading installations and over 40 onshore facilities for major oil & gas companies worldwide.

Click the tiles below to explore some of our recent projects for evidence of our expertise :-

Ithchys LNG

The Ichthys LNG project features monumental semi-submersibles, a massive FPSO, and the longest subsea gas pipeline in the region. Its extensive well footprint, spanning an area as vast as Perth, culminates in significant onshore LNG processing facilities, marking a milestone in energy infrastructure.

RESL created a fully costed decommissioning plan, click details.

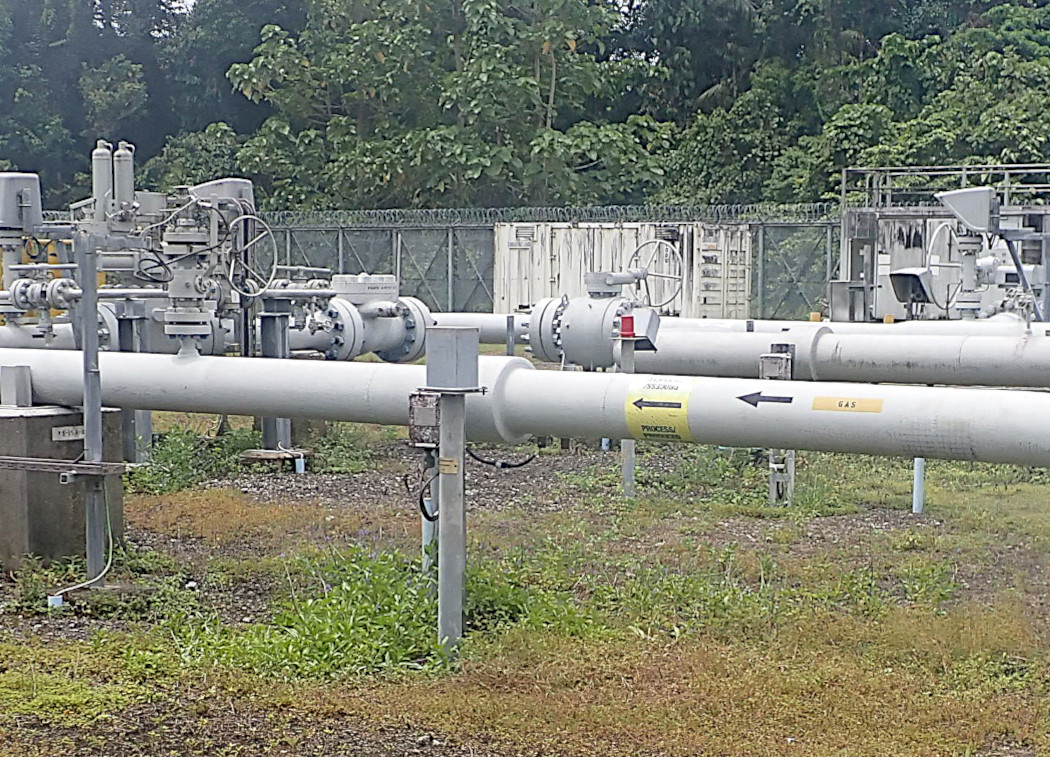

Gobe End of Field Life

Decommissioning in PNG's Gobe rainforest poses unique challenges: inaccessible terrain, environmental sensitivities, and logistical complexities demanded innovative solutions for successful restoration amid dense biodiversity.

Select details to find how RESL delivered

Agincourt Field (Quadrant Energy)

The well depicted above is part of an expansive study encompassing over 110 wells, including those within the Agincourt field, situated in the marine stretch between Barrow and Varanus Islands.

Pipeline 8

Not all our work is of a large scale this example is a smaller section of a larger project.

Contact us to find out more details about pipeline decommissioning

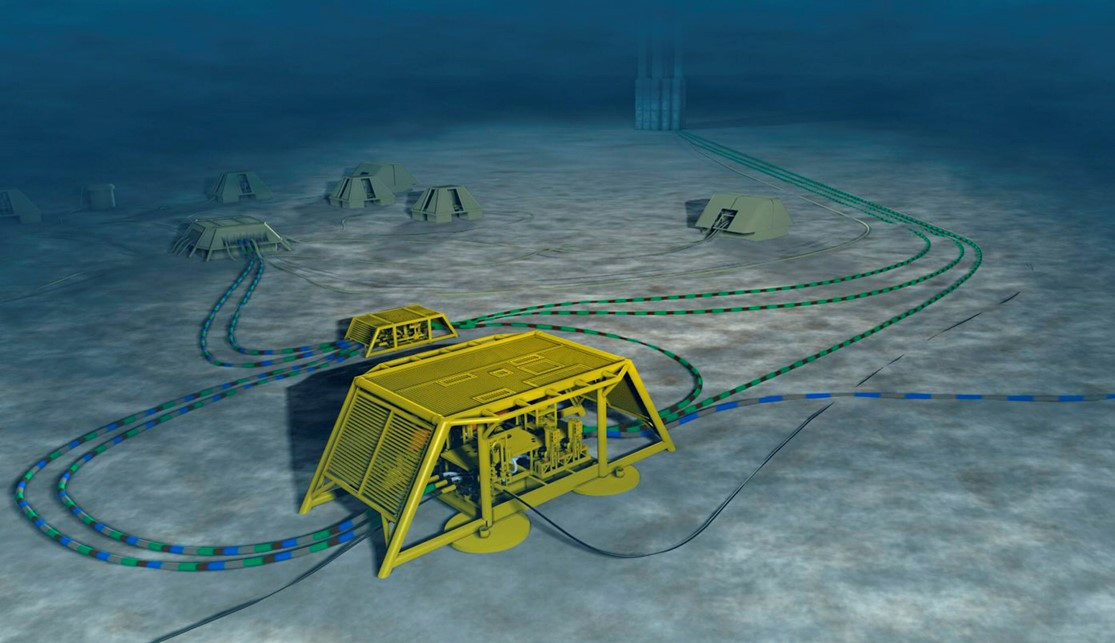

Subsea

RESL boasts deep expertise in executing subsea decommissioning, seamlessly integrating such operations within larger project frameworks or as standalone endeavors.

Ship Recycling

For over 15 years, RESL has actively participated in ship recycling, commencing with ARO studies focused on disposal routes for assets like large Semi Submersibles, FPSOs, and FSOs. Our scope has broadened to encompass waste disposal management and meticulous shipyard inspections, ensuring sustainable and responsible recycling practices.

Our Expertise.

RESL is a Specialist Consultancy with over 30 years' Experience solely focusing on Decommissioning of Facilities, Pipelines and Wells – Onshore, Offshore and Subsea.

Wells.

RESL offers extensive expertise in well abandonment across the globe, including North Sea, U.S., South East Asia, Australia, West Africa, and Brazil. Our experienced team handles onshore and offshore well abandonment using various methods, from traditional drilling rigs to innovative tooling, ensuring cost-effectiveness and risk reduction

Pipelines.

RESL has experience decommissioning of both onshore and offshore pipelines, including removal, abandonment and burial.

- Left in place or removal

- Evaluation off all decommissioning options

- Cleaning standards if leaving in place

- Handling of hazardous materials

Onshore.

This involves dealing with restricted access, noise abatement, relations with the local community and subsequent ground remediation uniquely posed by onshore locations, We work closely with the client’s team to identify the project specific issues, and then develop acceptable solutions minimising cost without compromising operational safety, or the quality of environmental controls..

Offshore & Subsea.

Ship Recycling.

With decades of hands-on experience, our team possesses the knowledge and skills required to safely and efficiently decommission ships and floating platforms. We understand the unique complexities that come with these projects, and our proven track record speaks volumes about our capabilities. Our environmentally conscious approach ensures that materials are recycled and disposed of responsibly, minimizing the environmental impact while maximizing resource recovery.

Wind.

Data collection forms the foundation of wind energy projects, aiding engineers in understanding operational dynamics. Deconstructing wind turbines and components reveals strengths and areas for improvement, driving innovation. This process also optimizes maintenance strategies, reducing downtime, and ensuring long-term success. In summary, Reverse engineering plays a pivotal role in advancing wind energy technology, optimizing performance, and promoting industry competitiveness.

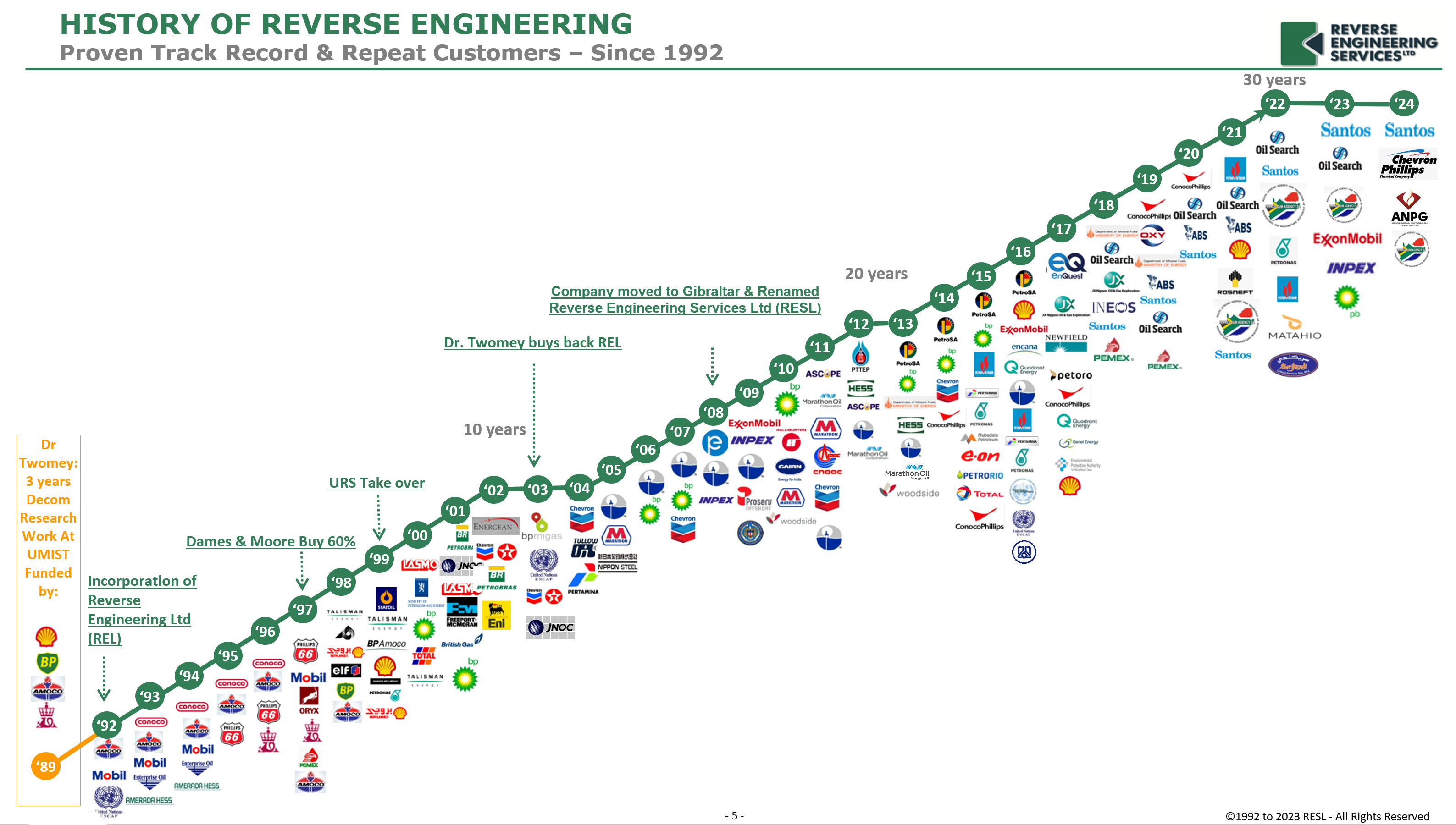

COMPANY HISTORY.

This chart shows our company evolution and the clients we have serviced from 1992 to current.

HOW WE WORK.

RESL helps formulate and shape national decommissioning policy and

guidelines.

Assisting both regulators and operators to interpret any national

regulatory frameworks.

We have an extensive decommissioning database, allowing for bench

marking of cost, duration and lessons learned from actual, completed

projects. The company constantly captures and transfers learning and

improvements from projects at different levels. These are the

six most common elements inherent in most of our work.

1. Legal & Regulatory Framework.

RESL offers services both in the creation of and operation within Legal & Regulatory Frameworks for decommissioning:

- Asset Specific Law & Regulations Review

- Legal & Regulatory Comparative Assessments and Gap Analysis

- Regulatory Requirements Interpretation

- Negotiations with Regulatory Authorities Development of Regional Decommissioning and Regulatory Authorities Development of Regional Well P&A Guidelines

- Preparation of Decommissioning Submissions

- Training of Regulators

2. Identify and Appraise Opportunity .

We offer the following services within the identify & appraise decommissioning project stage, covering facilities, pipelines and wells – onshore, offshore and subsea:

- Strategic Planning

- Process Development

- Cost Estimation

- Cost Verification

- Liability Management

- Data Gathering and Conditioning

- M&A Advice

3. Selection of Best Option.

We work with clients select the best decommissioning options minimizing cost in compliance with risk and the environment. We offers the following services within the Select Stage.

- Optimise with local law & regulations

- Risk strategy & risk analysis

- Effect of decommissioning on field development plan

- Optimise field design to minimize decommissioning costs

- Develop local contract strategy

- Solutions aiming for maximising local content

4. Definition of selected Concept.

We assist clients in defining selected decommissioning concept on the basis of sound engineering experience from similar projects delivering best practice project definition. RESL offers the following services within the Define Stage:

- Build accurate decommissioning data as is today

- Consider effect of all modifications on decommissioning cost

- Robust engineering and execute planning within law and regulations

- Risk identification and analysis

- HSE evaluations

5. Project execution.

We offer the following services within the Execute Stage, covering facilities, pipelines and wells – onshore, offshore and subsea:

- Capture all learning from completed projects

- Build in learning in future company decommissioning

- Client representative during decommissioning project execution

- Decommissioning project execution peer review

6. Monitoring & Evaluation.

We offer the following services within the Monitor & Evaluate stage to stakeholders including operators, partners, regulators, service companies and environmental groups:

- Lessons learned from decommissioning and well abandonment

- Best practice decommissioning derived from historical projects

- Recommended risk mitigating actions

- Post decommissioning and well abandonment survey planning

- Client representative during project monitoring

- Liability management

Meet Our Team.

Dr. Brian Twomey

Principal Consultant & Managing DirectorDr. Brian G. Twomey, Principal Consultant & Managing Director, oversees decommissioning operations, engineering, peer reviews, and cost analysis with 35+ years of experience. He's conducted decommissioning work on offshore installations worldwide across all continents. Dr. Twomey has presented 100+ papers on decommissioning and delivered extensive training courses.

Steve Coombes

Principle Consultant & Operations DirectorSteven Coombs, Principal Consultant and Operations Director, is a seasoned Petroleum Engineer with 37 years of expertise spanning reservoir, production, drilling, operations, cost estimation, and project management. He's contributed to decommissioning projects worldwide. Additionally, Steve excels in developing probabilistic models for cost estimating and oil and gas projects.

Jessica Courtoreille

HSE ManagerJessica Courtoreille, HSE Manager, has a wide ranging experience in development, operational and decommissioning in the oil and gas, transport and mineral extraction industries. A key skill in all of these has been communication and interaction with a variety of people and the development of trust relationships with Regulatory bodies and key stakeholders to facilitate the achievement of company requirements.

Get In Touch With Us.

RESL staff in the following international

locations.

United Kingdom

Portugal

Australia

United States

Head Office Postal Address

Reverse Engineering Services Ltd

16a Regents Road

Altrincham Cheshire

United Kingdom

CW12 1RP

Contact Number:

Phone: +44 (0) 7831 355 837

Email :